Manufacturing: Enhanced Linking of Production Orders

In MYOB Acumatica 2025.1, linking between parent and child production orders has been significantly enhanced. The following changes, which are described in the sections below, have been introduced:

- Improved visibility of related production orders

- Enhanced numbering of subassembly orders

- Allocation of a subassembly as a material to another production order

- Enhanced generation of orders for subassemblies

- Enhancements in finite production scheduling

Improved Visibility of Related Production Orders

In previous versions of MYOB Acumatica, it was not possible to display all dependencies of a production order in a single view. Production managers had to select each material line in a production order on the Production Order Details (AM209000) form to see its child orders, which was inconvenient and time-consuming.

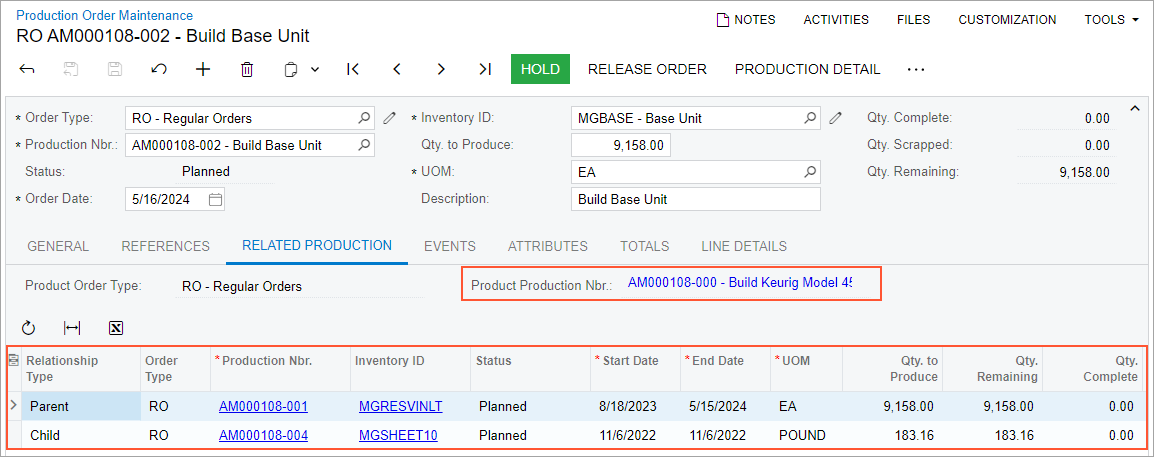

To address this issue, the new Related Production tab has been added on the Production Order Maintenance (AM201500) form. The tab displays the product production order (that is, the top-level production order), immediate parent production order, and immediate child production orders in a single view along with the details of these related production orders. (See the following screenshot.)

The Related Production tab only displays production orders that have an item plan linked directly to the current production order and production orders to which the current production order's item plan is linked as a supply. Consequently, if a user cancels or deletes a production order or production material demand, the item plan is removed and the system updates all parent and child relationships displayed on the Related Production tab accordingly.

To avoid the display of duplicate information, the Linked Orders section has been removed from the References tab of the Production Order Maintenance form.

Enhanced Numbering of Subassembly Orders

In previous versions of MYOB Acumatica, it was not possible to distinguish linked production orders (that is, the parent and child production orders) by looking at their identifiers.

Starting in MYOB Acumatica 2025.1, users can set up the system to assign the product production order and all its child production orders identifiers that have the same segment and a unique suffix. This makes it easier for users to identify production orders that are part of the same production bill of material (BOM).

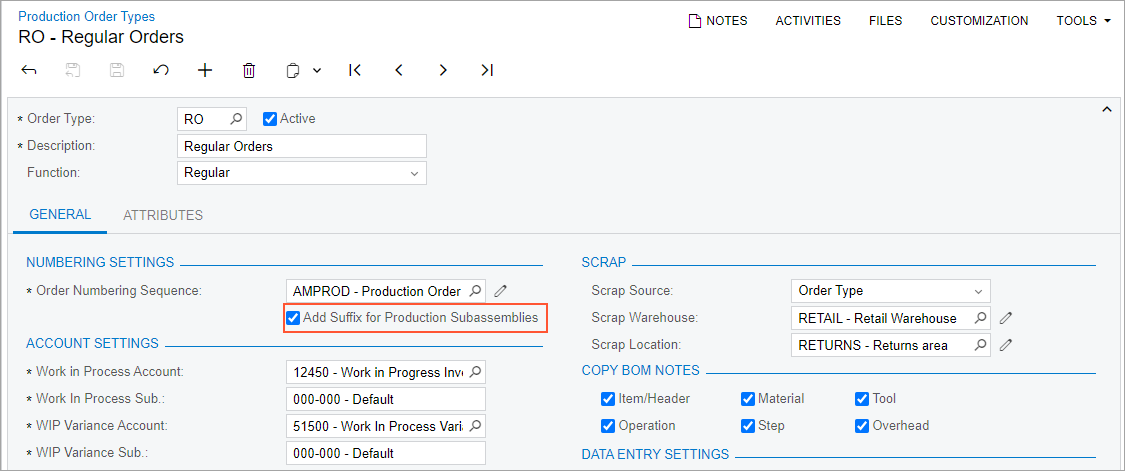

To support this functionality, on the Production Order Types (AM201100) form, the new Add Suffix for Production Subassemblies check box has been added to the General tab (Numbering Settings section), as shown in the following screenshot.

If the check box is cleared, the system generates the identifiers of production orders based on the production order numbering sequence, as it did in previous versions. If the check box is selected, the system assigns the identifiers as follows:

- The common segment of the identifier is generated based on the production order numbering sequence. Its length is shortened by four digits.

- The product production order (that is, the top-level production order) is assigned the common segment of the identifier followed by -000.

- All child orders of the product production order are assigned the common segment of the identifier followed by a hyphen and an incremental three-digit suffix. The incremental suffix is assigned sequentially from the top down, first to each immediate child production order, and then to the related production orders on each subsequent level in the order hierarchy.

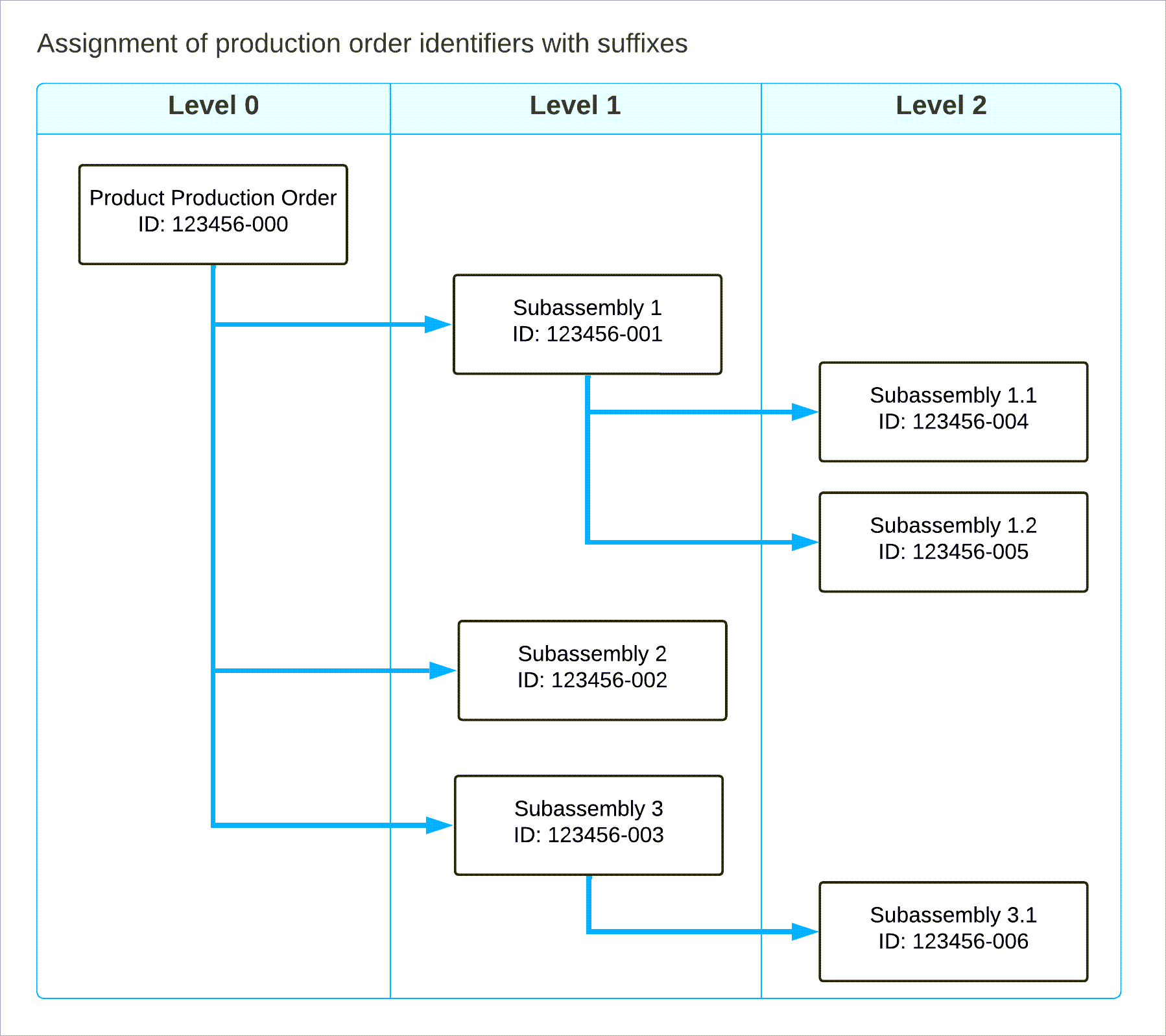

The following diagram illustrates the assignment of identifiers to the related production orders.

The system assigns the incremental suffix to related production orders when a user generates these orders on the following forms:

- Production Order Maintenance (AM201500)

- Sales Orders (SO301000)

- Inventory Planning Display (AM400000)

- Projects (PM301000)

- Estimate (AM303000)

- Create Production Orders (AM510000)

- Critical Materials (AM401000)

The Add Suffix for Production Subassemblies check box is cleared by default for all new and existing production order types.

Allocation of a Subassembly as a Material to Another Production Order

In previous versions of MYOB Acumatica, for an item produced in the scope of a subassembly production order, production managers had to wait until the item was moved to inventory before they could allocate it as a material to a parent production order. MYOB Acumatica 2025.1 introduces the ability to allocate an existing subassembly as a material to a parent production order.

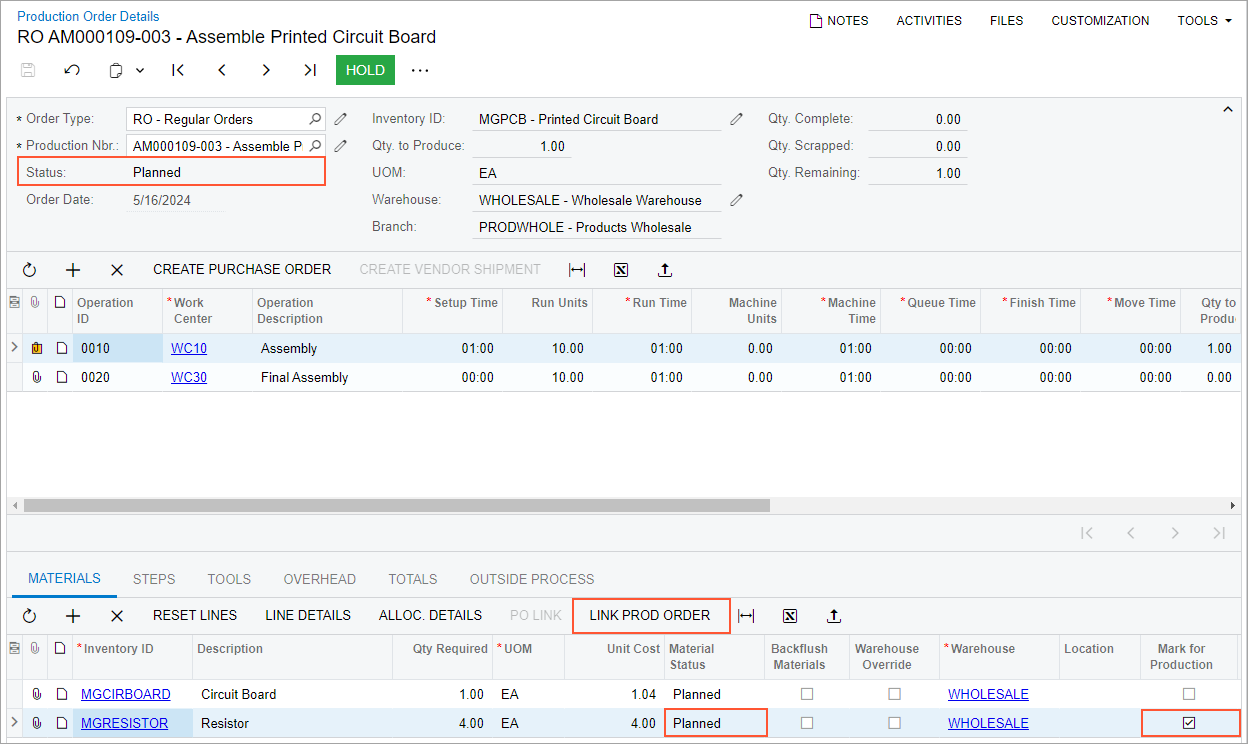

On the Production Order Details (AM209000) form, the Link Prod. Order button has been added to the table toolbar on the Materials tab, which is shown in the following screenshot. A user can link a production order's material demand to a subassembly production order if the following conditions are met:

- The production order has the Planned or On Hold status.

- The Mark for Production check box is selected in the material line.

- The line's material is not linked to any subassembly production order.

- The status of the line's material is Planned, Released, or In Process.

When a user clicks a material line and clicks Link Prod. Order, the new Production Details dialog box opens. This dialog box displays production orders for the item specified in the selected material line if they have the Planned, On Hold, Released, or In Process status and are not allocated to any other parent production order.

When the user selects a subassembly production order in the dialog box and clicks Save, the system updates the allocation type of that production order from Production Supply Prepared to Production for Prod. Prepared on the Inventory Allocation Details (IN402000) form. Also, the system updates the product, parent, and child relationships on the Related Production tab of the Production Order Maintenance (AM201500) form for all related production orders.

Generation of Orders for Subassemblies

In previous versions of MYOB Acumatica, users could generate subassembly production orders on the Production Order Maintenance (AM201500) and Critical Materials (AM401000) forms. However, this functionality was not available on any other forms that support the creation of production orders.

Now users can generate subassembly production orders on the following forms:

- Create Production Orders (AM510000)

- Sales Orders (SO301000)

- Inventory Planning Display (AM400000)

- Projects (PM301000)

- Estimate (AM303000)

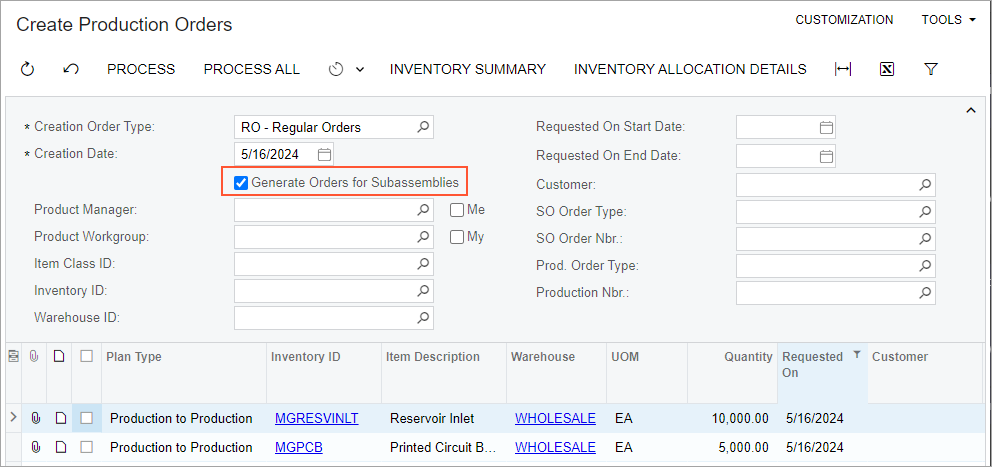

On the Create Production Orders form, the Generate Orders for Subassemblies check box has been added to the Selection area. If a user selects this check box, for each item selected in the table, the system creates a production order along with all required subassembly production orders.

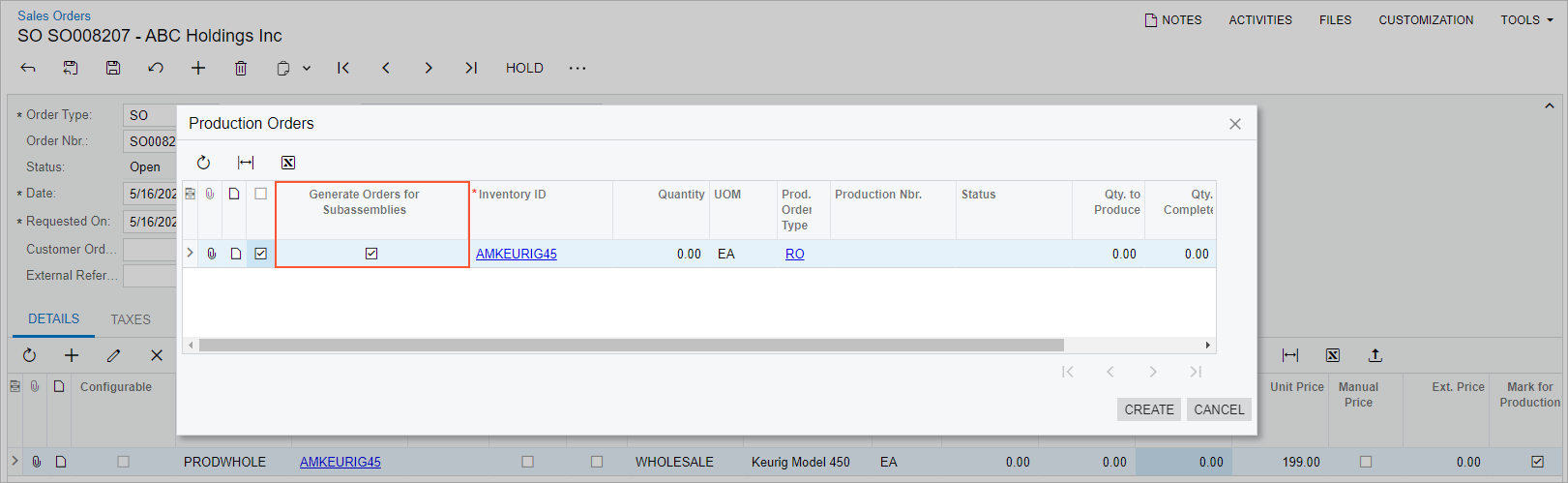

On the Sales Orders form, the Generate Orders for Subassemblies column has been added to the Production Orders dialog box (see the following screenshot), which opens when a user clicks Create Production Orders on the More menu. If the Generate Orders for Subassemblies check box is selected for a sales order line that has been marked for the creation of a production order (that is, a line with the unlabeled check box selected), the system creates a production order for the line's stock item along with all required subassembly production orders.

On the Inventory Planning Display form, the Generate Orders for Subassemblies column has been added to the Create Production Orders dialog box, which opens when a user clicks Manufacture on the form toolbar. If the user selects the Generate Orders for Subassemblies check box in a row with an item that has been marked for the creation of a production order (that is, a row with the unlabeled check box selected), the system creates a production order for the item along with all required subassembly production orders.

On the Projects form, the Generate Orders for Subassemblies check box has been added to the Create Production Orders dialog box, which opens when a user clicks Create Prod. Order on the toolbar of the Production Orders tab. If the user selects this check box, the system creates a production order for the specified inventory item along with all required subassembly production orders.

On the Estimate form, the Generate Orders for Subassemblies check box has been added to the Create Production Order dialog box, which opens when a user clicks Create Production Order on the More menu. If the user selects this check box, the system creates a production order for the estimate along with all subassembly production orders required for the estimate.

Also, in previous versions of MYOB Acumatica, when a user generated subassemblies by clicking Generate Orders for Subassemblies on the More menu of the Production Order Maintenance form, for each material line, the system created a production order if the following conditions were met for the material line's stock item on the Manufacturing tab of the Item Warehouse Details (IN204500) or Stock Items (IN202500) form:

- The Default BOM ID has been specified.

- The replenishment source is set to Manufacturing.

Now the system checks the state of the Mark for Production check box for the production material line on the Production Order Details (AM209000) form and creates a subassembly production order only if this check box is selected.

Enhancements in Production Scheduling

If a finished product is meant to be sold, and at least one of its subassemblies is engineered to order, production should be scheduled so that all dependent components are produced prior to the final assembly of the finished product.

MYOB Acumatica 2025.1 introduces improvements to the finite scheduling functionality, which is available when the Advanced Planning and Scheduling feature is enabled on the Enable/Disable Features (CS100000) form. Now the system considers the constraints of related production orders, along with the availability of work centers and machines. For example, if a parent production order is scheduled along with all of its child production orders on the Rough Cut Planning (AM501000) form, the system schedules the child production orders in such a way that they can be completed in time to be issued to the parent production order.

Also, in previous versions, a user could encounter unexpected results when they were scheduling a production order on the Rough Cut Planning and Production Order Maintenance (AM201500) forms and the system calculated the production order's scheduled start date to be in the past. In this case, the system would automatically reschedule the production order by changing its Scheduling Method to Start On and its Constraint Date to the current date. Now the system does not automatically update the constraint date and scheduling method for a product production order or for child production orders that are scheduled individually. Instead, if a user sets the Scheduling Method to Finish On and the system calculates the production start date to be in the past, a notification is shown. Similarly, the system displays warnings if updating the constraint date of a parent or child production order will result in the inability to produce subassemblies to fulfill the parent order's demand on time.

Other Improvements

In the Production Order Maintenance (AM2015PL) list of records and on the Material Wizard (AM300010) form, the following columns have been renamed for improved clarity:

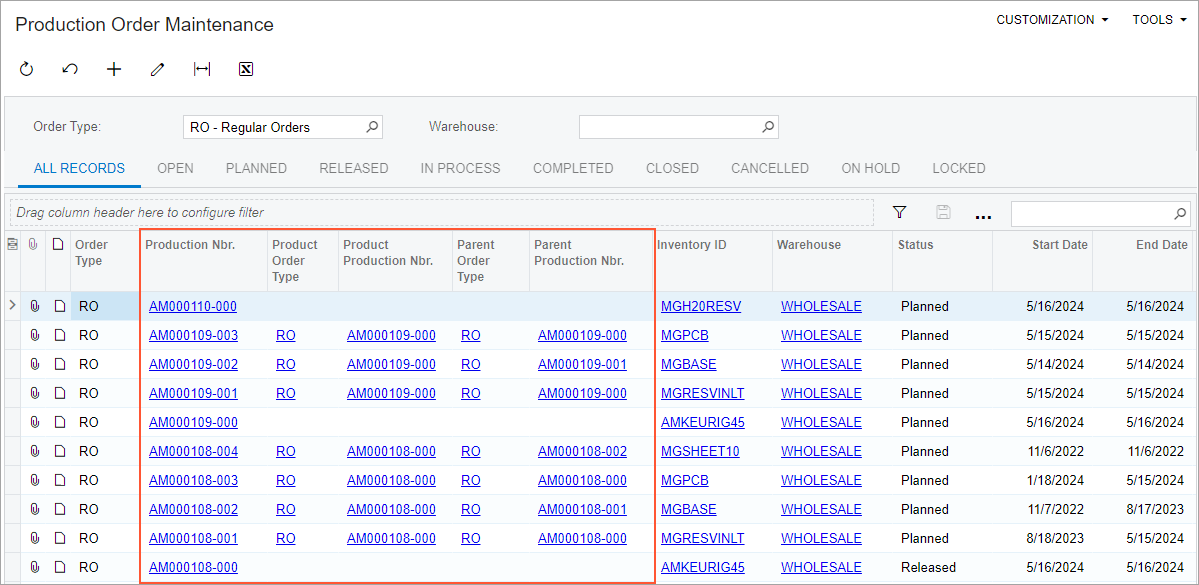

- Product Order to Product Production Nbr.

- Parent Order to Parent Production Nbr.

The Product Order Type, Product Production Nbr., Parent Order Type, and Parent Production Nbr. columns are now displayed on the following forms:

- Release Production Orders (AM500000)

- Close Production Orders (AM506000)

- Print Production Orders (AM511000)

- Rough Cut Planning (AM501000)

- Lock Production Orders (AM517000)

- Transactions by Production Order (AM000011)

- Production Summary (AM000006)

- Production Order Maintenance (AM2015PL)

The following screenshot shows how these columns help to identify related orders in the Production Order Maintenance list of records.

The same columns are also displayed in the lookup table for the Production Nbr. box on multiple forms.

The system now displays confirmation dialog boxes when a user does the following on the Production Order Maintenance (AM201500) and Production Order Details (AM209000) forms:

- Deletes or cancels a production order that has child production orders

- Removes material demand linked to another production order

- Deletes an operation whose materials are linked to other production orders