Manufacturing: Due Date Handling in Production Orders

In previous versions of MYOB Acumatica, production orders whose start and end dates were updated during the finite scheduling in advanced planning and scheduling (APS) did not retain the due dates of their linked or pegged demands. This could affect the production manager's confidence in the production schedule because tracking of potentially late production orders often involved manual effort, which could lead to errors.

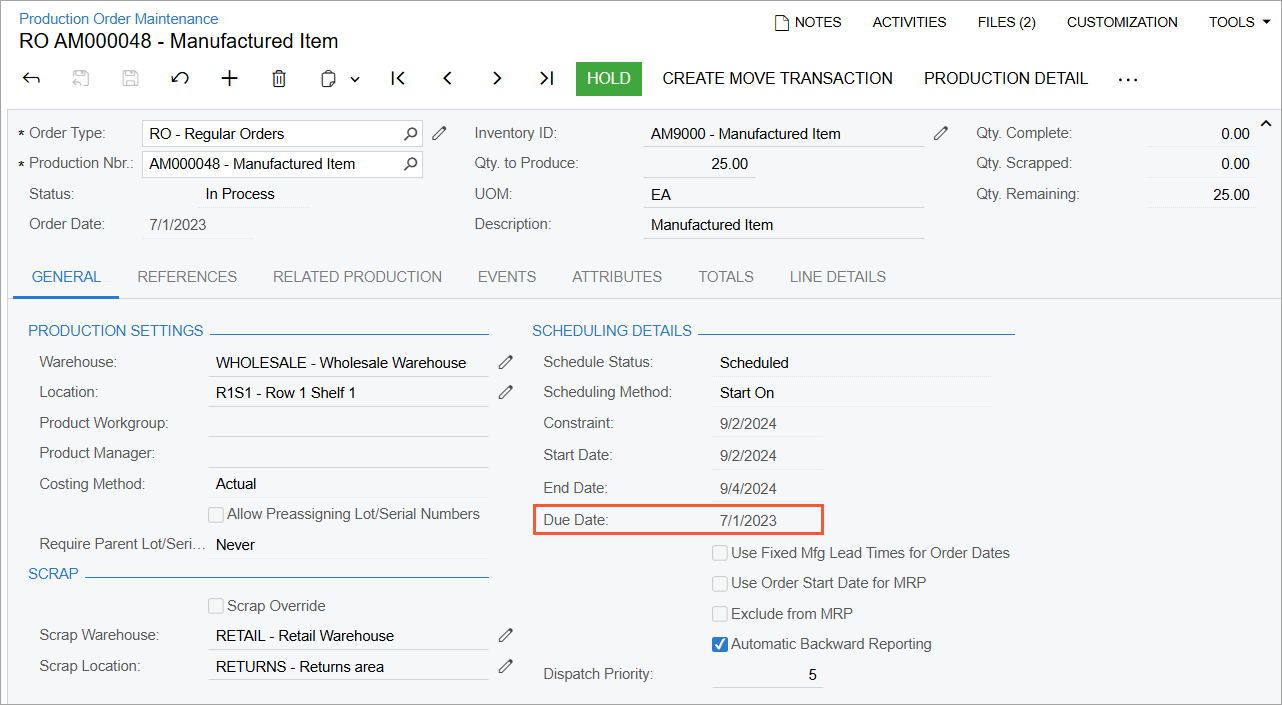

In MYOB Acumatica 2025.1, a new box, Due Date, has been added in the Scheduling Details section on the General tab of the Production Order Maintenance (AM201500) form, as shown in the following screenshot. This box holds the date by which the production order is expected to be completed to ensure on-time delivery for the pegged demand.

The Due Date box is useful in various production scenarios, including the following:

- Rescheduling production orders to prioritize rush sales orders

When production orders are canceled or rescheduled, the scheduler can now see the original Ship On date on the production order to adjust priorities accordingly.

- Fulfilling sales orders with updated ship-on dates

If the customer's required delivery date changes, production and scheduling teams can see the updated Ship On date and adjust production schedules as needed.

- Managing parent production order demand

The scheduler can now track the parent production order’s needed date for components and identify delays in child production orders when adjusting the schedule.

- Handling MRP-generated make-to-stock production orders

The production manager can preserve the original demand date by ensuring the Promised Date from the Inventory Planning Display (AM400000) form is reflected on the production order, helping prevent stockouts.

- Manually creating production orders

The production manager can define and retain the completion date of manually created orders, ensuring visibility for schedulers when making scheduling adjustments.

- Identifying delayed production orders on the Production Schedule Board

The scheduler can quickly spot late production orders that must fulfill linked demand, using the Ship On date as a reference. Delayed orders are also visually highlighted in the grid view on the Production Schedule Board (AM215555) form.

- Tracking lead time gaps between production completion and supply date

The system now calculates lead time gaps between production completion and supply dates, providing visibility into the Ship On date of the related sales order line.

The Due Date box is editable if there's no linked demand and the order is on hold.

If the production order is linked to a sales order line or a parent production order, the due date is determined as follows:

- If a sales order line is specified in the SO References section on the References tab of the Production Order Maintenance form, the Ship On date of the linked sales order line is automatically used as the due date of the production order. Any changes to the ship-on date update the due date accordingly. If the sales order is unlinked, the due date remains unchanged, but the Due Date box becomes editable.

- If a production order with the Parent relationship type is specified on the Related Production tab of the Production Order Maintenance form, the system uses the earliest allocation date of the inventory item if it is used as a material in an operation in the related production order. If the allocation date changes, the due date updates accordingly. If the related production order is deleted, the due date remains unchanged, but the Due Date box becomes editable.

If the production order has no linked demand, the system sets its due date to the date specified in the Promise Date column on the Inventory Planning Display form when the production order is created through that form.

The system will log an event on the Events tab of the Production Order Maintenance form when the production order's due date has been assigned or updated. This allows users to track who and when assigned or modified the due date, providing information for investigating changes that led to delayed or expedited production orders.

To improve visibility of the required supply dates for planning, scheduling, and tracking, the system also displays the due dates on the following forms:

- Production Schedule Board (AM215555)

- Production Summary (AM000006)

- Release Production Orders (AM500000)

- Rough Cut Planning (AM501000)

- Work Center Schedule (AM000001)