Manufacturing: Enhanced Material Availability and Production Readiness Tracking

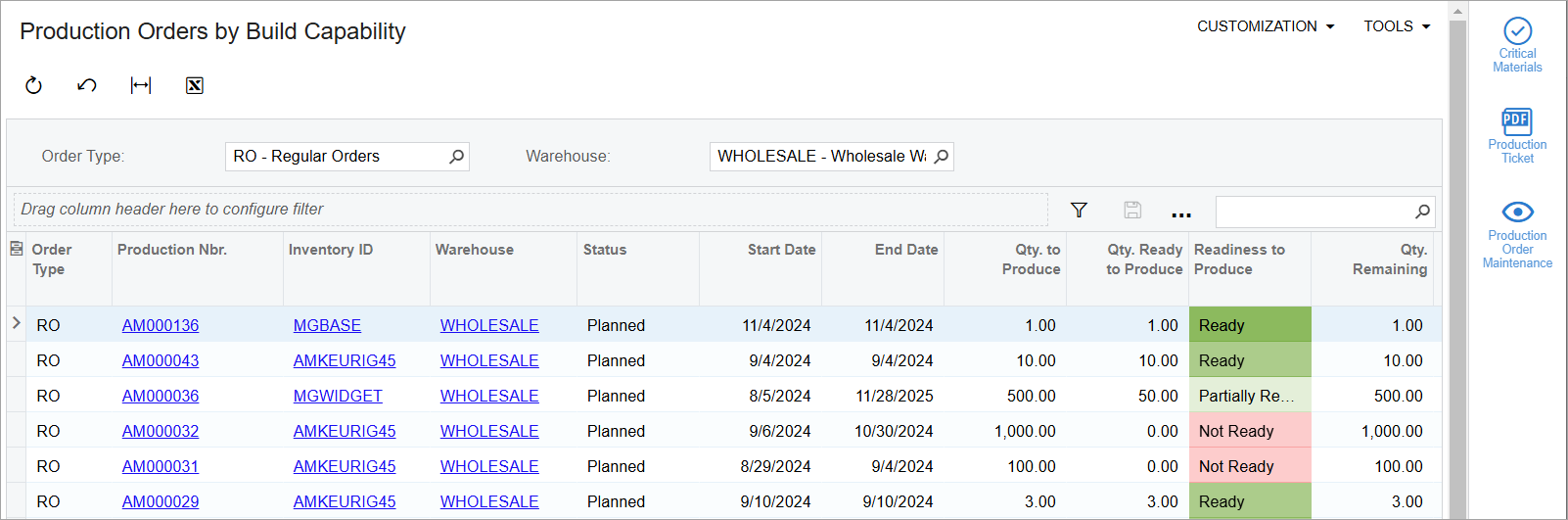

In MYOB Acumatica 2025.1, a new inquiry form, Production Orders by Build Capability (AM409000), has been introduced. This inquiry form (shown in the following screenshot) provides advanced tools for improving production planning efficiency by providing real-time insights into material availability. This enhancement supports production managers and planners in making more informed decisions and streamlining their workflows.

Each production order displayed on this form is assigned a readiness status, enabling users to quickly assess whether orders can be initiated based on material availability. Color coding is applied to highlight the readiness of production orders, particularly those with insufficient materials for production. The following readiness statuses are available:

- Ready to Produce (dark green): All materials are available to produce the remaining quantity.

- Partially Ready to Produce (light green): Materials are sufficient to produce a portion of the remaining quantity.

- Ready to Start (yellow): Materials are available to complete the first operation.

- Not Ready (red): Materials are insufficient to complete the first operation.

The inquiry form has a side panel with the following tabs for streamlined planning:

- Production Order Maintenance: Provides quick access to additional production information for detailed review.

- Critical Materials: Enables planners to create supply records for addressing material shortages.

- Production Tickets: Allows production managers to print necessary documents for production orders being released into production.

In the out-of-the-box system, a user can find the link to this inquiry form in the Production Orders workspace under the Inquiries category.

These changes simplify the process of evaluating material readiness, improve transparency in production planning, and enhance the ability to address material shortages proactively. Production managers and planners can now rely on more precise insights and efficient tools to ensure production schedules are met and supply chain disruptions are minimized.