Scrap Cost Calculation: To Process a Production Order with No Scrap Settings

The following activity will walk you through the process of recording item production that includes scrapped items when no specific actions are required for scrapped items.

Story

Suppose that the GoodFood One Restaurant has ordered three juicers from the SweetLife Fruits & Jams company. The production process includes the assembly and packing of the juicers. In the production process of SweetLife Fruits & Jams, materials and labor are backflushed for the packing operation. Further suppose that components for the juicers are available in SweetLife Fruits & Jams's warehouse.

Also suppose that during juicer assembly, a shop-floor employee assembled one of the juicers but found out that it does not work. The production manager asked the employee to record this juicer as scrap. Because the customer expects to have all three juicers at the same time, the employee assembled one extra juicer because the broken juicer must be scrapped and cannot be used to fulfill the customer's order.

Suppose that scrap is very rare on this shop floor, so scrapped items are not tracked by a warehouse and the scrap cost is applied to the cost of produced items.

Also suppose that the system should use the Actual costing method for calculating the unit cost of produced juicers because produced items are moved to stock only when all transactions have been released and all costs have been applied to a production order.

Acting as a production manager, you will create a production order for producing three juicers and process all related transactions. In a production environment, a shop-floor employee would create labor and move transactions on their own. To streamline this activity, you will enter this transaction as a production manager.

Also, acting as a production accountant, you will review scrap costs applied to the production order.

Configuration Overview

In the U100 dataset, the following tasks have been performed to support this activity:

- On the Warehouses (IN204000) form, the WORKHOUSE warehouse has been defined, and its locations include MGI and MTL.

- On the Stock Items (IN202500) form, the CFJFRUITBF, PULPCONT1L, JUICECUP05L, MRBASE, FNSIEVE, GRDISC01, PACKTAPE, PPEANUTS, and PACKBOX stock items have been defined.

Process Overview

In this activity, to process the documents and transactions related to the production of the juicers, you will do the following:

- On the Production Order Maintenance (AM201500) form, create and release the production order.

- On the Materials (AM300000) form, issue the materials required for the assembly operation.

- On the Labor (AM301000) form, record the labor spent on the juicer assembly, the produced quantity, and the scrapped quantity.

- On the Production Order Details (AM209000) form, review the production order balance after the assembly operation.

- On the Move (AM302000) form, record the produced items for the packing operation.

- On the Production Order Maintenance form, review the production order balance after you have completed the order.

- On the Close Production Orders (AM506000) form, close the production order.

System Preparation

Do the following:

- As a prerequisite to the current activity, complete Configuration of Production with Backflushing: Implementation Activity so that the system is ready for processing the production of juicers with labor and material backflushing.

- Launch the MYOB Acumatica website, and sign in to the company in which the prerequisite activity have been performed. You should sign in as the production manager by using the peters username and the 123 password.

- In the info area, in the upper-right corner of the top pane of the MYOB Acumatica screen, make sure that the business date in your system is set to today’s date. For simplicity, in this activity, you will create and process all documents in the system on this business date.

Step 1: Creating the Production Order

To create the production order for three juicers, do the following:

- On the Production Order Maintenance (AM201500) form, add a new record.

- In the Summary area, specify the following settings:

- Order Type: RO (selected automatically)

- Inventory ID: CFJFRUITBF

- Warehouse: WORKHOUSE (selected automatically)

- Location: MGI (selected automatically)

- Order Date: Today's date (selected automatically)

- Description: Production of 3 juicers

- On the General tab, do the following:

- In the Qty. to Produce box, specify 3.

- In the Costing Method box, select Actual.

- On the form toolbar, click Save.

- On the More menu (under Processing), click

Release Order. The order's status is changed to

Released.Tip: You open the More menu by clicking the More button (…) on the form toolbar.

Step 2: Issuing Materials for the Assembly Operation

Suppose that you have been informed that the shop-floor worker had to assemble one extra juicer because one of the assembled juicers did not work. Therefore the worker used more materials than it was planned. In this step, you will issue the needed material quantity for the assembly operation of the production order. Do the following:

- While you are still viewing the production order on the Production Order Maintenance (AM201500) form, on the More menu (under Transactions), click Release Materials. The system opens the Material Wizard (AM300020) form with the list of materials needed for the assembly operation.

- On the form toolbar, click Select All. The system creates the material transaction and opens it on the Materials (AM300000) form.

- In the Quantity column of each material line, specify 4. Notice that the system displays the warning that you are going to issue more materials than it is needed to produce the planned item quantity.

- In the Summary area, do the following:

- In the Description box, specify Materials for the assembly operation.

- Clear the Hold check box. The system changes the transaction's status to Balanced.

- On the form toolbar, click Release. The system releases the material transaction and changes the status of the transaction to Released.

Step 3: Recording the Labor, Produced Items, and Scrapped Items for the Assembly Operation

Suppose that Carlos Cruz, a worker in the work center, spent 30 minutes setting up the working environment for juicer assembly and assembled three juicers for one hour; one of the juicers does not work and must be recorded as scrap. To fulfill the production order, Carlos assembled one more juicer for 20 minutes. To record the time spent on juicer assembly, the assembled quantity of juicers, and the scrapped juicer, do the following:

- On the Production Order Maintenance (AM201500) form, open the production order you created earlier in this activity.

- On the More menu (under Transactions), click Create Labor Transaction. The system creates the labor transaction for the 0010 operation and opens it on the Labor (AM301000) form.

- Add the columns with scrap settings to the table as follows:

- In the table header, click the Column Configurator icon on the left to open the Column Configurator dialog box.

- Move the following columns to the Selected

Columns list:

- Scrap Action

- Qty is Scrap

- Click OK to save your changes and close the dialog box.

- Make sure that these columns have appeared in the table.

- In the row that the system added for the 0010 operation, specify the

following settings:

- Employee ID: EP00000027 (Carlos Cruz)

- Shift: 0001

- Labor Time: 01:50

- Quantity: 3

- Enter the scrap quantity as follows:

- In the Scrap Action column, make sure that No Action is selected.

- In the Qty Scrapped column, type 1.

- In the Summary area, do the following:

- In the Date box, make sure that the today's date is specified.

- In the Description box, specify Recording the time for assembly of 3 juicers, the completed quantity, and the scrapped quantity.

- Clear the Hold check box. The system changes the transaction's status to Balanced.

- On the form toolbar, click Release. The system creates and releases the cost transaction to record the labor costs and releases the labor transaction.

Step 4: Reviewing the Production Order Balance

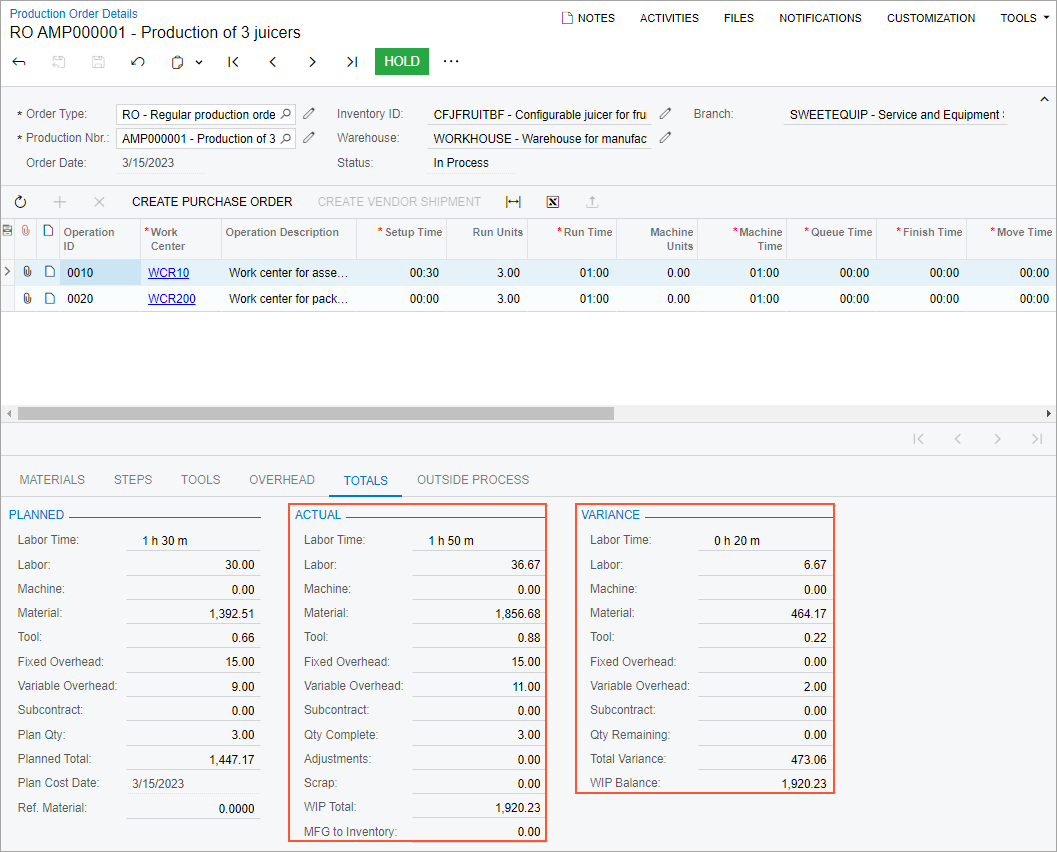

In this step, acting as a production accountant, you will review the balance of the production order after you have recorded the completion of the assembly operation. Do the following on the Production Order Details (AM209000) form:

- Open the production order you created earlier in this activity.

- In the Operations table, click the row for the 0010 operation.

- On the Totals tab, review the production order balance as

follows (see the screenshot below):

- In the Actual section, make sure that the

following values are displayed:

- Labor Time: 1 h 50 m

- Labor: 36.67

- Material: 1856.68

- Tool: 0.88

- Fixed Overhead: 15.00

- Variable Overhead: 11.00

- Scrap: 0.00 (for the No Action scrap action, scrap costs are included in the cost of the completed items)

- WIP Total: 1920.23 (which is the sum of the actual costs applied to the production order)

- MFG to Inventory: 0.00 (no items have been moved to stock yet)

As you can see, the system applied the costs of the assembly operation to the production order.

- In the Variance section, make sure that the

following values are displayed:

- Labor Time: 0 h 20 m

- Labor: 6.67

- Material: 464.17

- Tool: 0.22

- Variable Overhead: 2.00

- Total Variance: 473.06 (which is the sum of the variance costs)

- WIP Balance: 1920.23

The variance is caused by the costs of the scrapped juicer. The Total Variance box by fact contains the cost of the scrapped juicer, which the system added to the cost of the completed juicers.

Figure 1. Production order balance for the assembly operation

- In the Actual section, make sure that the

following values are displayed:

Step 5: Recording the Produced Items for the Packing Operation

Suppose that a worker in the packing work center has packed the assembled juicers. To record the completion of the packing operation, do the following:

- On the Production Order Maintenance (AM201500) form, open the production order you created earlier in this activity.

- On the More menu (under Transactions), click Create Move Transaction. The system creates the move transaction for the 0020 operation and opens it on the Move (AM302000) form.

- In the Summary area, do the following:

- In the Date box, make sure that the today's date is specified.

- In the Description box, enter Recording the completion of packing 3 juicers.

- Clear the Hold check box. The system changes the transaction's status to Balanced.

- On the form toolbar, click Release. The system releases the move transaction. Also, the system creates and releases a cost transaction for backflushed labor and a material transaction for backflushed materials. You can view these transactions on the Events tab of the Production Order Maintenance form. The packing operation is the last operation in the routing so the system changes the status of the production order to Completed.

- On the Receipts (IN301000) form, open the receipt with the today's date, the total quantity of three CFJFRUITBF items, and the total cost of 1943.39.

- In the Unit Cost column of the only row, make sure that 647.7970 is specified.

Step 6: Reviewing the Balance of the Completed Production Order

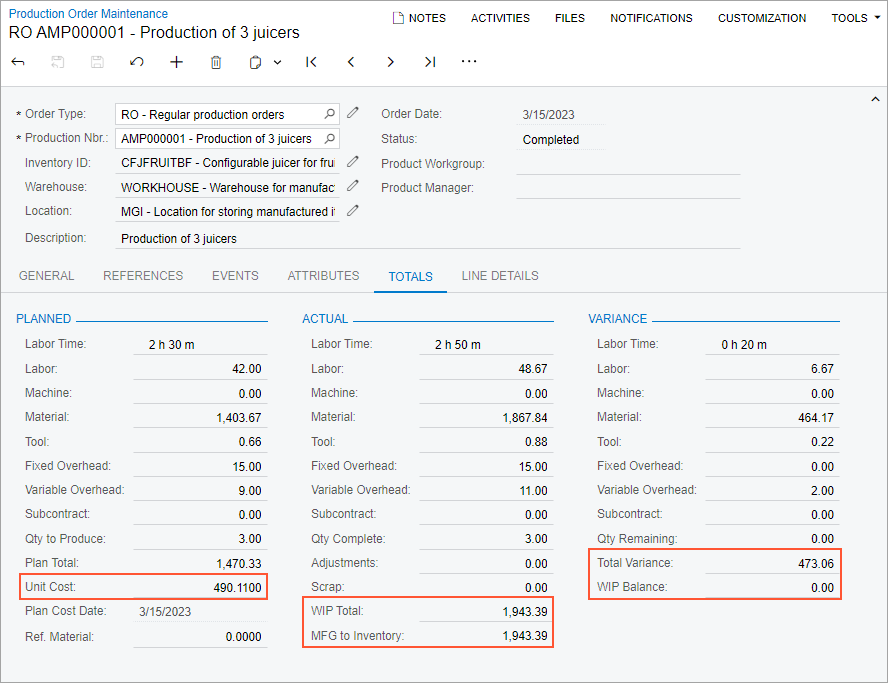

In this step, acting as a production accountant, you will review the production order balance after you have recorded the completion of the packing operation. Do the following on the Production Order Maintenance (AM201500) form:

- Open the production order you created earlier in this activity.

- On the Totals tab, review the production order balance as

follows (see the following screenshot):

- In the Planned section, make sure that the value of the Unit Cost box is 490.1100.

- In the Actual section, make sure that the values of the WIP Total and MFG to Inventory boxes are 1943.39, which is the cost of three produced items plus the cost of the scrapped item. The cost of one item is 647.7970, which equals the unit cost in the inventory receipt. To calculate the unit cost, the system divided the actual costs applied to the production order by the completed quantity.

- In the Variance section, make sure that the value in the Total Variance is 473.06, which means that it has not been changed since the assembly operation has been completed.

- Make sure that the value of the WIP Balance box is 0.00, which means that the actual costs of the production order have been fully applied to the cost of the produced items.

Figure 2. Production order balance after the completion of the order

Step 7: Closing the Production Order

Now you will close the production order. Do the following:

- On the Close Production Orders (AM506000) form, select the production order.

- On the form toolbar, click Process. In the Processing dialog box, which opens, review the processing details, and when the processing is completed, click Close.

- Go to the Production Order Maintenance form, and notice that the status of the production order has changed to Closed.

You have successfully created the production order for the assembly and packing of three juicers, processed all the transactions related to the production, recorded a scrapped item, and reviewed the costs of the production order.