Packing Operations: Process Activity

In the following activity, you will learn how to perform the packing of items for a shipment by using the Pick, Pack, and Ship (SO302020) form.

Story

Suppose that you are a warehouse worker of the wholesale warehouse of the SweetLife Fruits & Jams company. Your warehouse manager gives you a task to pack a shipment. In your organization, the pack workflow is used, which means that you go through the warehouse locations, take the items, and pack the items into boxes for shipping.

Configuration Overview

In the U100 dataset, the following tasks have been performed to support this activity:

- On the Enable/Disable Features (CS100000) form, the

following features have been enabled in the Inventory and Order

Management group of features:

- Multiple Warehouse Locations

- Warehouse Management

- Fulfillment

- On the Warehouses (IN204000) form, the WHOLESALE warehouse has been created. On the Locations tab, the following warehouse locations have been defined: L3R2S2 and L2R1S3.

- On the Stock Items (IN202500) form, the

following stock items have been created, and the corresponding alternate IDs

with the Barcode type have been defined on the

Cross-Reference tab:Tip:For simplicity, in this activity, the alternate IDs will be further referred to as barcodes.

- APJAM08, which has the AJ08 barcode

- ORJAM32, which has the OJ32 barcode

- On the Boxes (CS207600) form, the MEDIUM box has been defined.

- On the Sales Orders (SO301000) form, the 000032 sales order for the COFFEESHOP customer has been created.

- On the Shipments (SO302000) form, the 000031 shipment has been created for this sales order.

Process Overview

In this activity, acting as a packer, you will do the following:

- Open the Pick, Pack, and Ship (SO302020) form and scan the number of

the shipment. Then you will scan the following barcodes required for the

shipment packing:

- The box to which you pack the items

- The location from which you take the items

- The packed items

- The quantities of the packed items.

When the packing is finished, you will confirm the shipment.

- Review the shipment.

System Preparation

Before you start the automated packing operations, you need to perform the following instructions:

- Sign in to a company with the U100 dataset preloaded as a warehouse worker with the perkins username and the 123 password.

- On the Warehouse Management tab of the Sales Orders Preferences (SO101000) form, do the following:

- Clear the Display the Pick Tab check box.

- Make sure that the Display the Pack Tab check box is selected.

- On the form toolbar, click Save.

Step 1: Packing Items for Shipping

To record that items to be added to a shipment have been picked from the warehouse locations and packed into boxes, do the following:

- Open the Pick, Pack, and Ship (SO302020) form, and make sure the

Pack tab is opened.Tip:If the Pack tab does not appear by default, you can type @pack in the Scan box and press Enter to switch to Pack mode.

- In the Scan box, enter 000031, which is the reference number of the shipment for which you are performing picking and packing operations. The system loads the shipment lines to the table on the Pack tab, and shows the reference number of the shipment that is currently being processed in the Shipment Nbr. box of the Summary area.

- Enter MEDIUM to select the box to which the items are packed.

- Enter L3R2S2 to specify the first location from which the items are taken.

- Enter AJ08 to pack the item. (AJ08 is the barcode

for APJAM08, the 8-ounce jar of apple jam, which is included in the

000031 shipment.)

The system highlights the first line of the shipment in bold and specifies 1 as the Picked Quantity and Packed Quantity.

- Set the quantity of the current line to 10 as follows:

- On the form toolbar, click Set Qty. The system prompts you to enter the item quantity.

- In the Scan box, type 10. The system highlights the first line of the shipment in green and specifies 10 as the Picked Quantity and Packed Quantity.

- Enter L2R1S3 to specify the next location from which the items are taken.

- Enter OJ32 to pack the item. (OJ32 is the barcode for ORJAM32, the 32-ounce jar of orange jam, which is included in the 000031 shipment.)

- Set the quantity of the item to 7.

- On the form toolbar, click Confirm Package to confirm the package.

- On the form toolbar, click Confirm Shipment to confirm the shipment document, which is assigned the Confirmed status.

Step 2: Reviewing the Shipment

To review the result and make sure that the shipment has been confirmed, do the following:

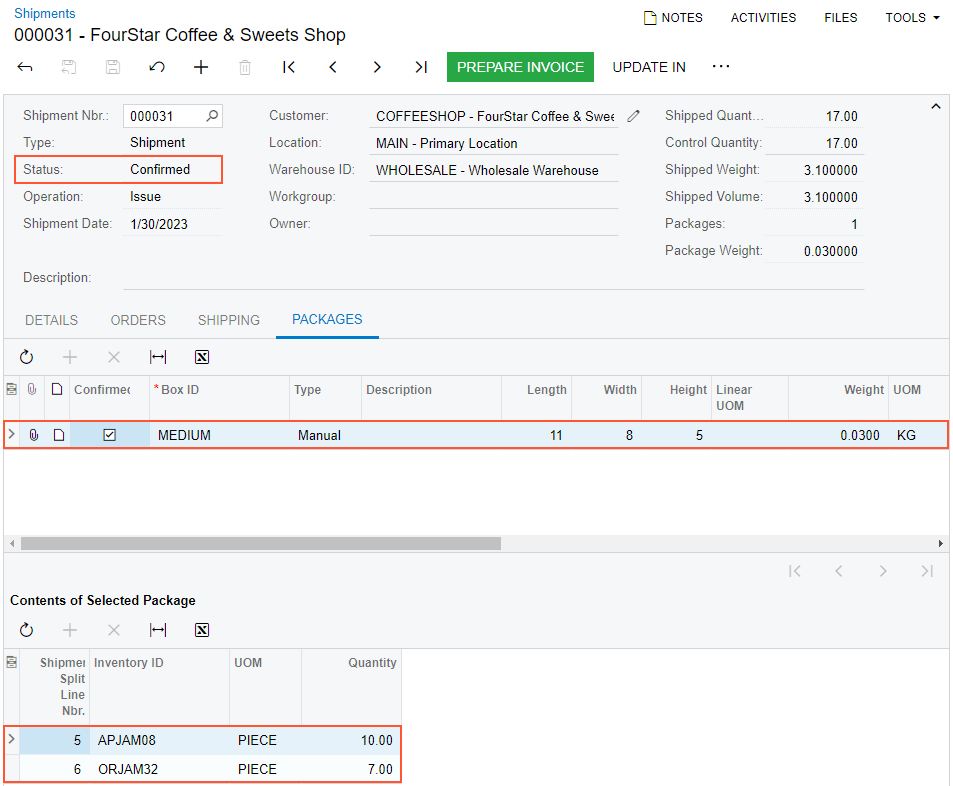

- While you are still viewing the shipment on the Pick, Pack, and Ship (SO302020) form, click the Edit button next to the Shipment Nbr. box. On the Shipments (SO302000) form, which opens, review the shipment that you have processed in the previous step. It is now assigned the Confirmed status.

- Review the Packages tab. Notice that one MEDIUM

box is shown in the upper table, and the Contents of Selected

Package table shows the items that you have packed into this

box, as shown in the following screenshot.

Figure 1. Confirmed shipment

Step 3: Resuming the Picking of Items for Shipment on the Pick Tab

Suppose that you need to process the shipment for which you are performing picking and packing operations. To cause the system to show the Pick tab on the Pick, Pack, and Ship (SO302020) form, do the following:

- On the Warehouse Management tab of the Sales Orders Preferences (SO101000) form, select the Display the Pick Tab check box.

- On the form toolbar, click Save.