Automated Operations with Lot- and Serial-Tracked Items: To Issue Items

In this activity, you will learn how to perform automated issuing of lot-tracked items.

Story

Suppose that you, as a warehouse worker of the SweetLife Fruits & Jams company, have a task to check the boxes of bananas in refrigerators in order to find rotten bananas and write them off. To record writing off boxes with rotten bananas in the system, you will create and process an inventory issue.

Configuration Overview

In the U100 dataset, the following tasks have been performed to support this activity:

- On the Enable/Disable Features (CS100000) form, the

following features have been enabled in the Inventory and Order

Management group of features:

- Multiple Warehouse Locations

- Lot and Serial Tracking

- Warehouse Management

- Inventory Operations

- On the Warehouses (IN204000) form, the WHOLESALE warehouse has been created. For this warehouse, on the Locations tab, the F2S2 and F3S2 warehouse locations have been added.

- On the Stock Items (IN202500) form, the BANANAS stock item has been created. For this stock item, the BBOX unit of measure has been defined on the General tab and the BNBOX barcode has been defined on the Cross-Reference tab of the form.

Process Overview

When you issue lot-tracked items in this activity, you will scan the barcode of the location where the items are stored; you then scan a barcode of each item to be issued and the barcodes of the lot numbers that correspond to each item. When you have added all items in all locations to the issue, you will release the issue.

System Preparation

Before you start issuing lot-tracked items, do the following:

- Sign in to a company with the U100 dataset preloaded. You should sign in as warehouse worker with the perkins username and the 123 password.

- On the Enable/Disable Features (CS100000) form, enable the Lot and Serial Tracking feature.

Step 1: Processing the Issue of Items

Suppose that when you were checking the boxes with bananas in the refrigerator locations, as instructed by your manager, you have found four boxes with rotten bananas: two boxes with different lot numbers in the F2S2 location, and two boxes with the same lot number in the F3S2 location. To process the issue transaction in the system, do the following:

- Open the Scan and Issue (IN302020) form.

- In the Scan box, type F2S2, which is the barcode of the location where the first box of bananas is stored. Press Enter.

- Enter BNBOX, which is the barcode that corresponds to a box of 10 pounds of bananas.

- Enter FR200384 to specify the lot number of the box. The system adds 1 unit of the BANANAS item in the BBOX unit of measure to the table on the Issue tab.

- Enter BNBOX for the second box of bananas.

- Enter FR200401 to specify the lot number of the box. The system adds 1 unit of the BANANAS item in the BBOX unit of measure to the table on the Issue tab.

- Enter F3S2, which is the barcode of the location where the second box of bananas is stored.

- Enter BNBOX to add the box of bananas.

- Enter FR200335 to specify the lot number of the box. The system adds 1 unit of the BANANAS item in the BNBOX unit of measure to the table on the Issue tab.

- Set the quantity to 2 as follows:

- On the form toolbar, click Set Qty. The system prompts you to enter the quantity.

- In the Scan box, enter 2. The system changes the quantity of the BANANAS item with the FR200335 lot number to 2.

- On the form toolbar, click Save. The system saves your changes and creates the inventory issue, whose identifier you can view in the Reference Nbr. box of the Summary area.

You have added four boxes of bananas to the issue. Now you will review the inventory issue and release the issue.

Step 2: Releasing and Reviewing the Issue

To release and review the issue, do the following:

- While you are still viewing the inventory issue on the

Issue tab of the Scan and Issue

(IN302020) form, make sure that the settings of the rows you have entered

correspond to the settings in the following table.

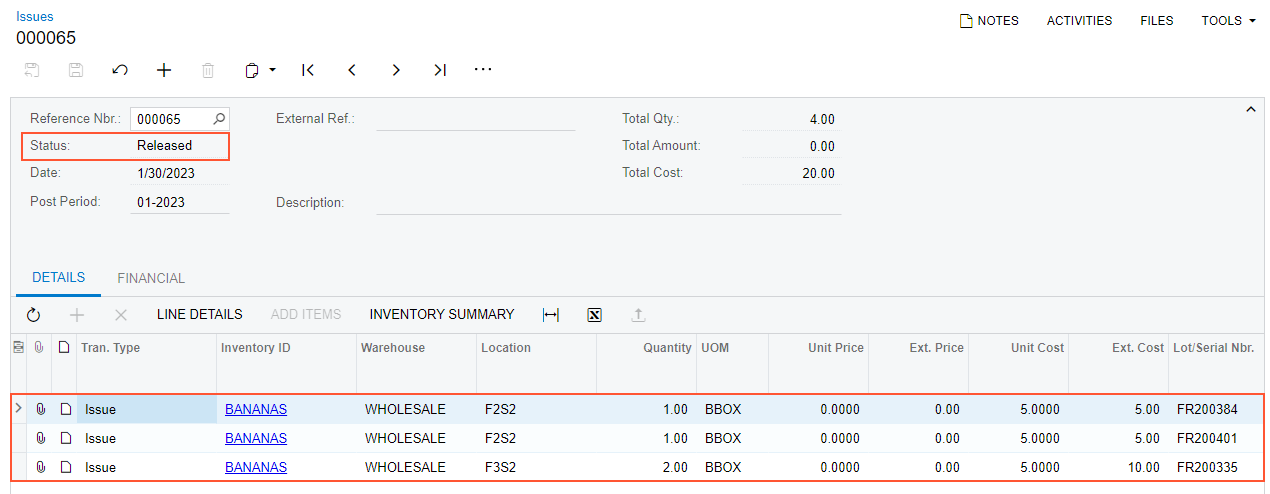

Inventory ID Lot/Serial Nbr. Expiration Date Location Quantity UOM BANANAS FR200384 2/3/2025 F2S2 1 BBOX BANANAS FR200401 2/6/2025 F2S2 1 BBOX BANANAS FR200335 2/4/2025 F3S2 2 BBOX - On the form toolbar, click Release to release the inventory issue.

- Click the Edit button next to the Reference Nbr. box, and

on the Issues (IN302000) form, which opens in a pop-up

window, review the inventory issue transaction. Make sure that it includes the

needed lines and is assigned the Released status, as shown in the

screenshot below.

Figure 1. Inventory issue transaction

You have successfully created and released the inventory issue to record the removal of four boxes of bananas from their warehouse locations.