Assigning Lot or Serial Numbers to Stock Items in Appointments

An appointment may include stock items. In some cases, lot or serial numbers need to be assigned to these stock items at the time they are used during the appointment, rather than when they are received in the warehouse. This is often necessary when, for example, the specific item to be installed at the customer location is unknown beforehand, and the technician needs to enter the relevant number during installation.

In MYOB Acumatica, a lot or serial number can be assigned to any stock item during an appointment on the Appointments (FS300200) form. For these numbers to be generated, the following settings must be specified in the stock item’s lot or serial class on the Lot/Serial Classes (IN207000) form:

- The Track Serial Numbers or Track Lot Numbers tracking method is selected.

- The When Used assignment method is selected.

This functionality applies only to customers with a billing cycle set up to process billing for appointments.

Methods for Generating Lot or Serial Numbers on the Appointments Form

On the Appointments (FS300200) form, you can view or generate lot or serial numbers for a stock item by clicking the item on the Details tab and then clicking Lot/Serial Nbrs on the table toolbar. Lot or serial numbers for stock items can be generated either manually or automatically, depending on the state of the Auto-Generate Next Number check box in the stock item's lot or serial class on the Lot/Serial Classes (IN207000) form:

- If the check box is selected, the system automatically generates lot or serial numbers

for each unit of the selected stock item on the Details tab of the

Appointments form. The lot or serial number or numbers

are displayed in the Lot/Serial Nbr. column in the Line

Details dialog box.

If the lot or serial class settings of the selected stock item require auto-generation of the lot or serial number, the Unassigned Qty. and Quantity to Generate boxes in the dialog box contain 0 by default. This is because the lot or serial numbers are automatically generated by the system when the appointment is saved.

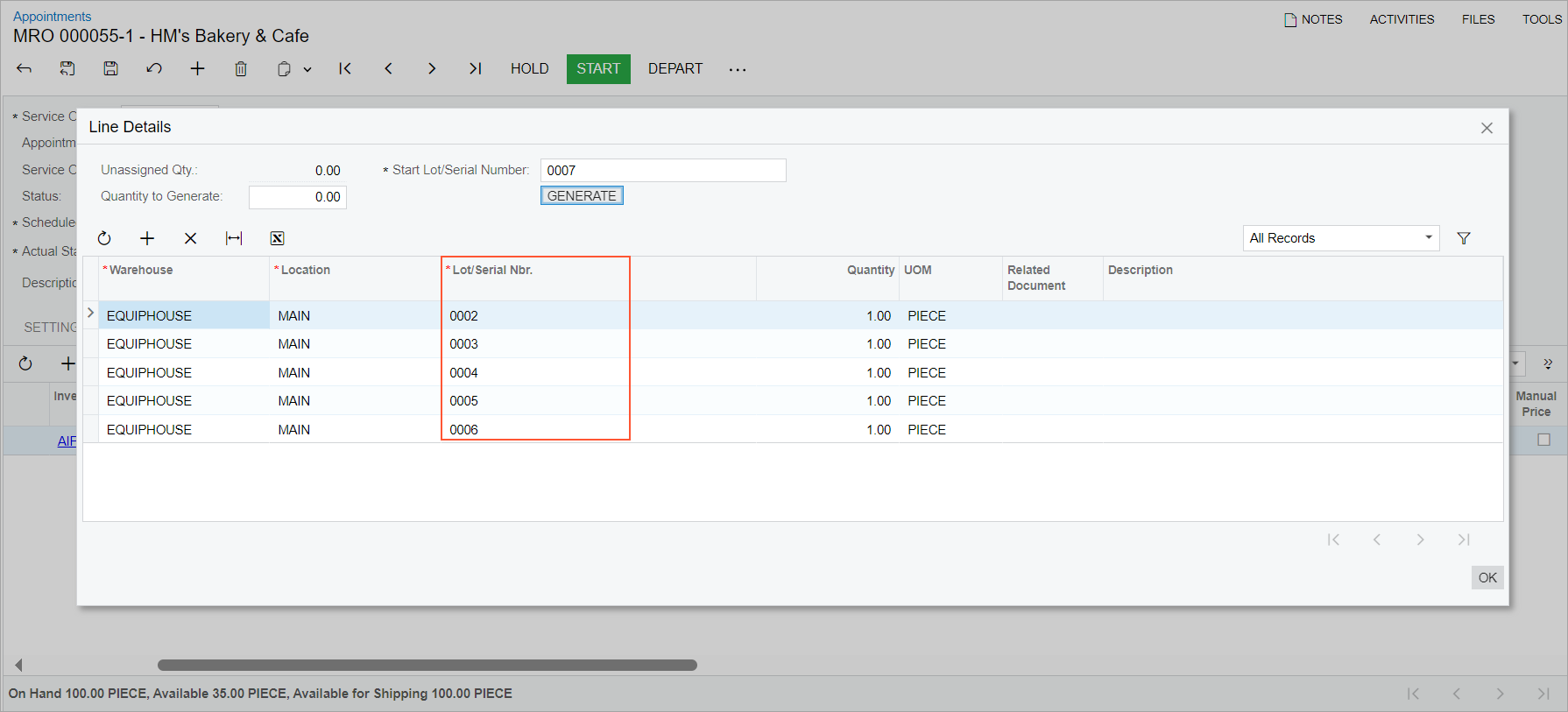

- If the check box is cleared, you must manually generate lot or serial numbers by

clicking the Generate button in the Line

Details dialog box.

When you click Generate, the system generates lot or serial numbers for the specified quantity of the stock item and displays the numbers in the Lot/Serial Nbr. column. In the following screenshot, serial numbers have been generated. (Note that the system generates a single lot number for all units of the selected item and lists it in the only row.)

Figure 1. The generated serial numbers

If a serial number is generated for a single unit of the stock item, the system creates one serial number and inserts it in the Lot/Serial Nbr. column of the item's line on the Details tab of the Appointments form.

If serial numbers are generated for multiple units of the item, the Lot/Serial Nbr. column in the item's line on the Details tab remains empty. However, when the appointment is billed each unit of the stock item will be listed in its own row in the invoice with its serial number in the Lot/Serial Nbr. column.