Bills of Material: Implementation Activity

In the following implementation activity, you will learn how to create a bill of material (BOM).

Story

Suppose that SweetLife Fruits & Jams has decided to assemble customized juicers according to customers' specifications. Assembly will take place in the Workhouse warehouse of the Service and Equipment Sales Center branch, in a specific work center. The process of assembling a juicer consists of one assembly operation and requires juicer parts as materials and a hammer and screwdriver as tools. Overhead costs have been specified at the work center level; you do not need to specify them on the bill of material. In the work center, two workers are involved in juicer assembly. Each worker produces three juicers per hour.

As an implementation manager, you will create the bill of material for the assembly process of the configurable juicer for citrus fruits.

Configuration Overview

The following entities, which you will use in this activity, have been predefined in the U100 dataset:

- On the Warehouses (IN204000) form, the WORKHOUSE warehouse

- The following items on the Stock Items (IN202500) form: CFJCITRUS, JCREAMER, JUICECUP1L, MRBASEHIGH, STRBASKET, and SPLGUARD

Process Overview

On the Bill of Material (AM208000) form, you will create the bill of material for the configurable juicer for citrus fruits. You will add the assembly operation, which is performed in the dedicated work center. Then you will add materials, steps, and tools for the operation. After that you will make the bill of material active and default for the juicer stock item. Finally, you will view the total cost of the bill of material.

System Preparation

Before you start performing the activity, do the following:

- As prerequisites to the current activity, perform the following activities in

the listed order:

- Configuring Production Cost Drivers: Implementation Activity so that the needed tools have been created in a company with the U100 dataset preloaded

- Configuring Work Centers: Implementation Activity so that the needed work center has been created in this company

- Sign in to this company (in which the prerequisite activities have been performed) as a system administrator with the gibbs username and 123 password.

Step 1: Creating a Bill of Material

To create a bill of material, do the following:

- On the Bill of Material (AM208000) form, add a new record.Tip:To open the form for creating a new record, type the form ID in the Search box, and on the Search form, point at the form title and click New right of the title.

- In the Summary area, specify the following settings:

- Revision: A (automatically specified)

- Hold: Selected

- Inventory ID: CFJCITRUS

- Warehouse: WORKHOUSE

- Start Date: 1/1/2024

- End Date: Empty

- Description: A bill of material for assembly of configurable juicers for citrus fruits

- On the form toolbar, click Save.

Step 2: Adding an Operation

To add the assembly operation to the bill of material, do the following:

- On the toolbar of the Operations table, click Add Row.

- In the row, specify the following settings:

- Operation ID: 010

- Work Center: WCR10

You created this work center in Configuring Work Centers: Implementation Activity.

- Setup Time: 00:30

- Run Units: 3

- Run Time: 01:00

- On the form toolbar, click Save.

Step 3: Adding Materials

To add the materials required for the operation, do the following:

- In the Operations table, click the row with the 010 operation.

- In the lower part of the form, click the Materials tab.

- On this tab, add rows for the stock items listed in the following table,

specifying the listed settings for each.

Inventory ID Qty. Required JCREAMER 1 JUICECUP1L 1 MRBASEHIGH 1 STRBASKET 1 SPLGUARD 1 - On the form toolbar, click Save.

Step 4: Adding the Steps

To add steps required to perform the operation, do the following:

- On the Steps tab, add rows for the steps, as shown in the

following table.

Description Line Order Attach the strain basket to the motor base. 10 Attach the reamer to the strain basket. 20 Attach the 1-liter juice cup to the motor base. 30 Attach the splash guard. 40 - On the form toolbar, click Save.

Step 5: Adding the Tools

To add the tools involved in the assembly process (you created these tools in Configuring Production Cost Drivers: Implementation Activity) to the operation settings, do the following:

- On the Tools tab, add rows for the tools listed in the

following table, specifying the listed settings for each.

Tool ID Qty. Required Unit Cost HAMMER 1 0.02 SCREWDRIVER 1 0.20 - On the form toolbar, click Save.

Step 6: Activating the Bill of Material

To make the created bill of material active and specify it as the default bill of material for the CFJCITRUS item, do the following:

- In the Summary area, clear the Hold check box. The status changes to Active.

- On the form toolbar, click Save.

- On the More menu, click Set as Default BOM.Tip:You open the More menu by clicking the More button (…) on the form toolbar.

- In the

Default BOM Levels dialog

box, which opens, do the following:

- Make sure that the Item and Warehouse check boxes are selected.

- Click Update.

The system inserts BOM000001 in the Default BOM ID box of the Manufacturing tab of the following forms:

- The Stock Items (IN202500) form for the CFJCITRUS item

- The Item Warehouse Details (IN204500) form for the CFJCITRUS item and WORKHOUSE warehouse

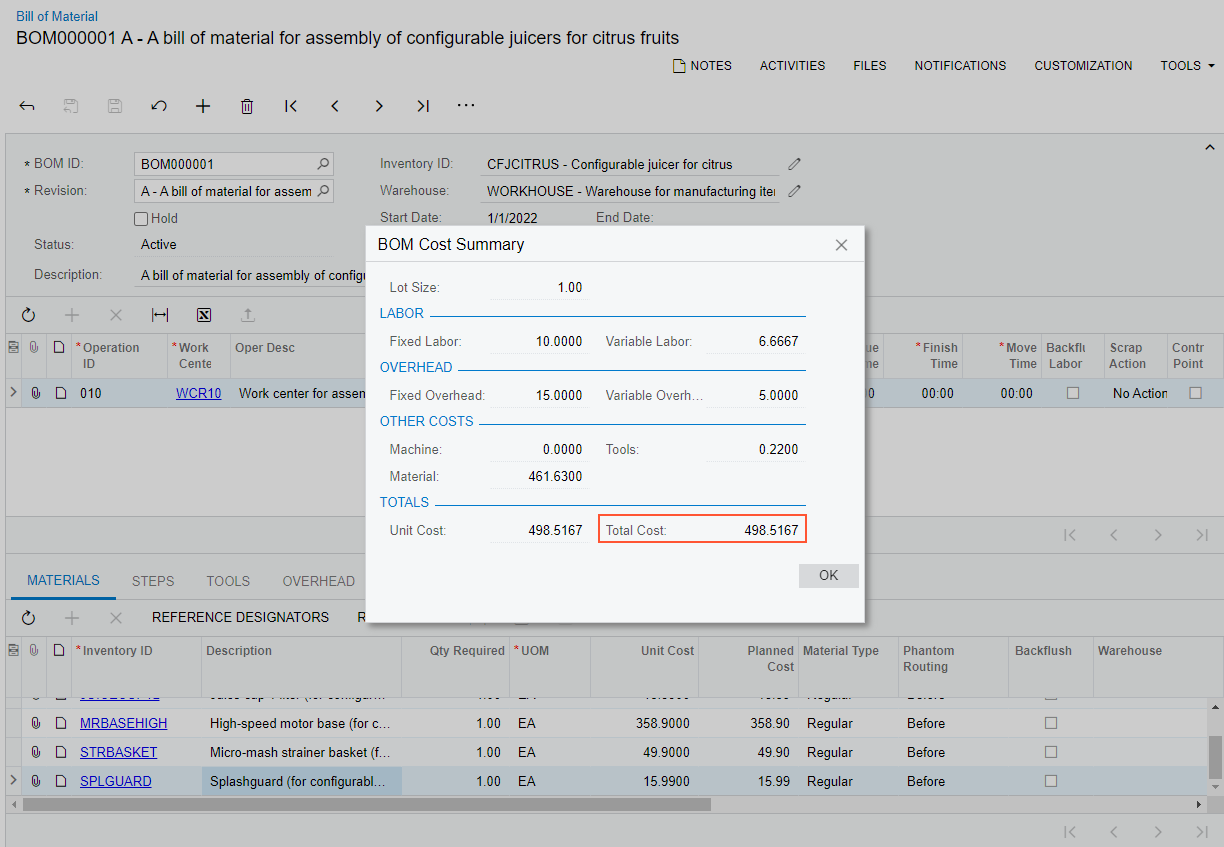

Step 7: Viewing Total Cost of Bill of Material

To make sure that you have specified all settings of the bill of material correctly, you will view the total cost of the bill of material. Do the following:

- On the More menu, click Calculate BOM Cost.

- In the BOM Cost Settings dialog box, which opens, keep the default settings and click OK.

- In the BOM Cost Summary dialog box, which opens, make

sure that the Total Cost value is 498.5167 (see

the following screenshot).

Figure 1. BOM Cost Summary dialog box

- Click OK to close the dialog box.

You have created the bill of material for the configurable juicer for citrus, made it active and default for the stock item that represents the juicer.