Creating a Works Order

Transactions > Manufacturing > Works Order Entry

A Works Order is a more complex version of a build-type Bill of Materials.

To create a Works Order:

-

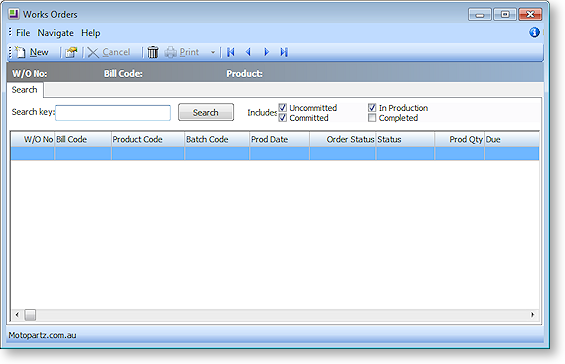

Select Works Order Entry from the Transactions > Manufacturing menu. The following window is displayed:

-

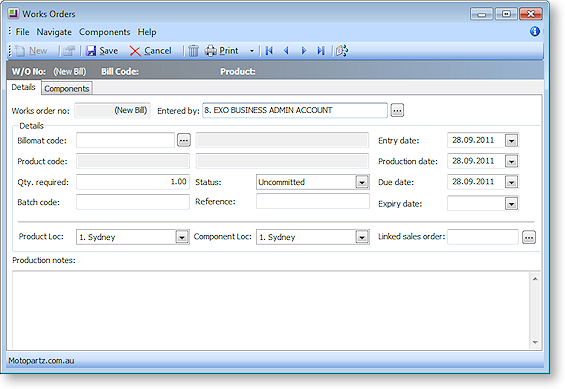

Click the New button. The following window is displayed:

-

Complete the fields on the Details tab.

Field

Description

Works order no

The number of the selected works order. This number is assigned when the Works Order is first saved.

Entered by

The name of the staff member entering the works order. Click the

button to select the staff member’s name.

button to select the staff member’s name.Billomat code

The Bill of Materials code. Click the

button to select a Bill of Materials. Only build-type Bills of Materials are available, as these are the only BOMs that undergo a manufacturing transformation.

button to select a Bill of Materials. Only build-type Bills of Materials are available, as these are the only BOMs that undergo a manufacturing transformation.Product code

The code of the Bill of Materials' output item.

Qty. required

The quantity to be produced.

Batch code

The production batch code. You can add this Works Order to an existing batch.

Status

The production status:

-

Uncommitted

-

Committed

-

In Production

-

Completed

Reference

An optional reference code. May be left blank.

Entry date

The start date for the Works Order.

Production date

The production date for the Works Order.

Due date

The date the Works Order is to be completed.

Expiry date

The date the Works Order expires.

Product Loc

The location to which the final product should be transferred.

Component Loc

The location that components are being supplied from.

Linked sales order

The number of the Sales Order that the works order is linked to. Click the

button to select a Sales Order. This field is optional.

button to select a Sales Order. This field is optional.Production notes

Any notes that you may need to make in relation to this works order.

-

-

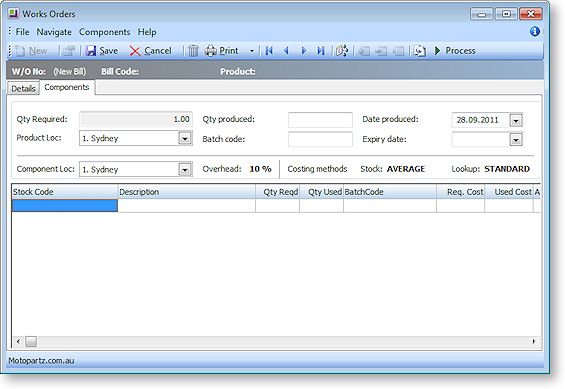

Click the Components tab.

-

Complete the fields at the top of the Components tab.

Field

Description

Qty Required

The total quantity to be produced.

Qty produced

The quantity to be produced in this operation.

Date produced

The date the works order is completed.

Product Loc

The location to which the final product should be transferred.

Batch code

The production batch code.

Expiry date

The date the Works Order expires.

Component Loc

The location that components are being supplied from.

-

Use the buttons on the toolbar to add or remove components:

Button

Function

Load all components from the Bill of Materials.

Add a component.

Remove a component.

Replace a component.

-

The following fields are displayed for each component:

Field

Description

Stock Code

The stock code of the item.

Description

The description for the item. Read only.

Qty Reqd

The quantity of the component required to fulfil the entire Works Order. Read only.

Qty Used

The quantity of the component to be consumed in this operation.

BatchCode

The production batch code.

Req. Cost

The total cost of the required number of the component. Read only.

Used Cost

The cost of the components consumed in this operation. Read only.

Analysis Codes

Any Analysis Codes you want to associate with the Works Order.

Clicking the

button sets the Qty Used value for all components to the Qty Reqd value.

button sets the Qty Used value for all components to the Qty Reqd value.You can double-click on an item to drill down to the Stock screen for that item.

-

Click Save. You are given the opportunity to print the Works Order.

Note: The Works Order will appear on the Works Order tab of any Stock item that is involved in it, either as a component or as an output item.