About Back Orders

Back Orders typically occur when a stock item is out of stock. The order quantity is recorded as a Back Order, to be supplied when you receive more quantity of the stock item. You can also use back orders to ration your available quantity of a stock item across a number of Sales Orders, to ensure each Sales Order is partly supplied.

In addition to the status of Back Order, there is also the status of Release. The Release quantity is the quantity of an undelivered stock item that remains allocated to a Sales Order. The sum of the Release and Back Order quantities equal the Sales Order quantity. If you adjust the Back Order quantity, the Release quantity is automatically adjusts.

For example, if you have a Sales Order of 10 of an item, but can only supply 5 of the 10, to ration out the shipment of the item you have just received, 5 have a status of Back order, and 5 have a status of Release.

Note: If you have Exo Business Configurator, you can turn this setting off by changing the Enforce constraint of sales order quantity and release quantity Company-level profile setting.

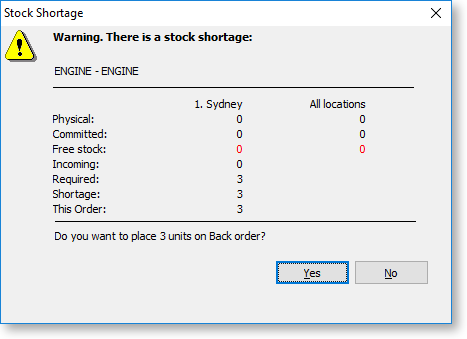

When you supply a Sales Order with insufficient stock to supply a line, the Stock Shortage window displays. You're prompted to back order the shortfall quantity:

Note: The Check available stock for sales orders profile setting affects the checks that determine when this window displays.

If you choose not to back order, the shortfall quantity displays as negative stock for the stock item. You can process the Sales Order.

This prompt is controlled by the Default response to backorder prompt User-level profile setting in Exo Business Configurator. By default it is already activated, but if you set it to Never, the Back Order prompt displays and no quantities are placed on back order.