Serial Number Processing

You maintain serial numbers when you create stock transactions for a serialised stock item. This is usually associated with a business document (for example, Debtor invoice). When you save a document, the stock items to serialise are determined based on the combination of the document class and the serial type of the stock items. The quantity of serials for each of these is computed.

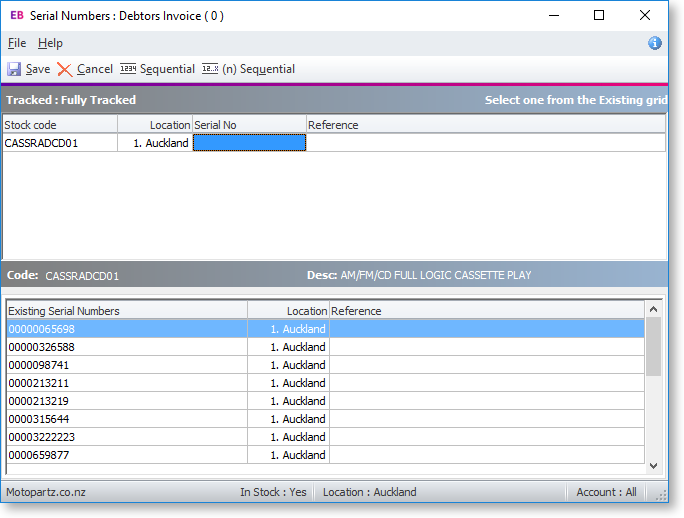

The top grid of the window contains the serialised rows, which is calculated from the line quantities of the parent document. Only items that should be considered serialised for this document class display. If no items require serial processing, then the Serials screen does not display and the transaction continues.

You can't delete or insert rows, as this would require altering the quantities on the parent document. You can click the Cancel button to discard serial information entered and return to the parent document. Clicking Save again returns to a fresh serials screen.

As the top grid is navigated:

-

The lower grey bar shows the stock item code and name, and the upper grey bar shows the serial number type and available actions.

-

The lower grid displays serial number list for the item in focus.

-

The status bar shows the filters that were applied in presenting this list and stock the stock status, location selection, and account selection.

The lower grid shows a list of available serials. When the item is for a contra (negative) quantity such as a credit note, the row in the upper grid is red and the lower grid contains a list of serials previously traded with this partner. The column header wording of the first column (for example, Existing Serial Numbers in the above example) also changes to reflect this.

Navigation and Data Entry

For some serial number types and document classes, the serial numbers must already exist in the list in the lower grid. In others, you must create them.

On the serial number screen:

-

When the cursor is in a Serial No cell of the upper grid, the left and right arrows move along this upper grid row. The up and down arrows move the selected line in the lower grid. If the cursor is in another upper grid column (for example, Expiry or Reference), then the up and down arrows navigate the top grid.

-

Entering, scanning, or selecting a serial number moves down one row.

-

If a serial number that you enter matches an entry in the lower list, it is selected. You can also select entries using the mouse or navigating the bottom grid and pressing enter. A selected serial copies all its static attributes such as Expiry and Reference.

-

Selected serials are hidden in the bottom grid so you can't select them more than once. If a serial is selected in error, select another. The serial that you select replaces the previous selection. The replaced serial becomes the last row on the bottom list.

Sequential Entry

After entering a serial number, click the Sequential or (n) Sequential buttons to enter or select sequential numbers for consecutive rows that have the same stock code.

When you click the Sequential button, Exo Business detects a change of stock code. Click the (n) Sequential button to request a quantity and recurse this many times or until a change of stock code (whichever comes first).

When using these functions to create new serials, the right-most portion of the serial number in focus is used as the incrementing integer. For example, if started with a serial in the form ABC-123-1001-Z, then 1001 is the portion incremented. The next serial is ABC-123-1002-Z. This function also clones the Expiry and Reference fields from the starting row.

When selecting existing serials Exo Business will select from the lower list in sequence. Expiry and Reference will be obtained from the selected serial.

Closing the Serials Window

When all rows of the upper grid are populated, click the Save button to close the Serials screen and save the transaction.

Clicking Save without all rows populated displays a warning before returning to the serials screen.

Clicking Cancel discards all changes you've made.

Pre-assignment

Pre-assigning serials follows the same workflow as stock transactions.

If serials have been pre-assigned, then when the serial selection screen re-opens (either for review or subsequent stock transitions), the serials previously assigned populate the upper grid.

If the quantity required in the current session is less than the quantity pre-assigned, the pre-assigned serial populates the upper grid in ascending Serial No. sequence (for example, a Sales Order for ten items may have ten pre-assigned, but only four are being supplied for the current session). The additional assigned serials display in the lower grid as rows with a different background colour. You can also choose a non-assigned serial as replacement.

If insufficient serials have been pre-assigned, blank serial number cells display and you must enter information in those cells.